Membrane technology for challenging separations: Removal of CO2, SO2 and NOx from flue and waste gases

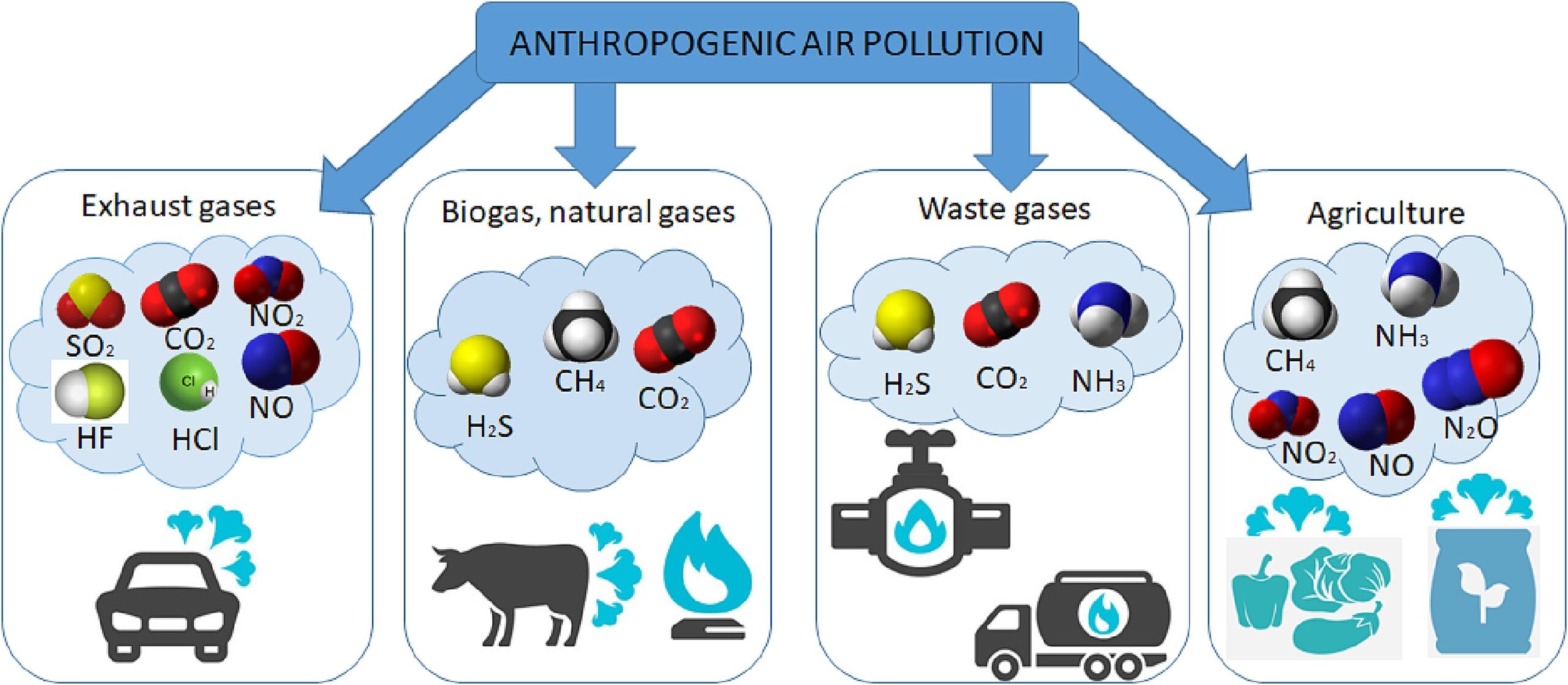

Based on the numerous studies that have been published so far, it can be stated that different membranes in different forms, with a wide range of chemical, physical, and transport properties and different operating principles, offer excellent possibilities for the efficient separation of different gas mixtures. While the performance of non-porous membranes has been explored in detail, there are still opportunities to further improve the separation performance of gas mixtures under more realistic operating conditions at different temperatures, pressures, and inlet compositions. This review article shows that membrane permeability studies with SO2 and NOx are rare and usually not fully explored in the industry in terms of temperature or gas mixture composition. Further study is required to assess in particular the influence of humidity and trace amounts of other impurities such as H2S, hydrocarbon vapors, and other source-specific chemicals (e.g. NH3, N2O, HCl).

New studies should also focus on the stability of achievable permeance over time, as many high-permeability membrane materials often undergo physical aging, resulting in a gradual and usually undesirable reduction in permeability. We also have to realize that the practical cleaning of flue gases is associated with huge volumes of gases, and therefore the compression work of compressing them would be very economically demanding. Therefore, only membranes with extremely high permeabilities of unwanted gases (i.e. CO2, SO2, NOx, H2S, and water vapor) have the potential for industrial scale-up.

The preparation of thin-film composite membranes with ultra-high permeability based on the described materials, such as PIM, MMM, and SILM, is, according to the overview, a minor step, although it is a necessary step for the application of membranes on a larger scale. It is also very important to focus on new technological devices and membrane modules, not just on the development of new materials in the laboratory. Both flat membrane modules (in the form of frame modules or spiral wound modules) and hollow fiber modules have their advantages and disadvantages, which are also evaluated in relation to the processes.

- Pasichnyk M., Stanovský P., Polezhaev P., Zach B., Šyc M., Bobák M., Jansen J.C., Přibyl M., Bara J.E., Friess K., Havlica J., Gin D.L., Noble R.D., Izák P.*: Membrane technology for challenging separations: Removal of CO2, SO2 and NOx from flue and waste gases. Sep. Purif. Technol. 2023, 323, 124436. doi: 10.1016/j.seppur.2023.124436