Microreaction and membrane technologies for continuous single-enantiomer production: A review

The separation of chiral substances is a priority research topic of the Department of Membrane Separation Processes of our institute. This research is supervised by Dr. Izák and it is focused primarily on understanding the principles of the separation and on the preparation of chiral membranes for effective separation of racemic mixtures. A review article devoted to this topic was recently published in the journal Catalysis Reviews as a result of cooperation of our institute with the Department of Chemical Engineering at the University of Chemistry and Technology in Prague which is focusing on micro-reactor technologies.

The article discusses the possibility of utilizing micro-reactor and membrane technologies as an integral unit for the continuous production of optically pure forms (enantiomers) of pharmaceutically relevant substances. Enantiomers are optically pure forms of the substance and they exhibit identical physico-chemical properties in a normal environment, however, their biochemical and pharmacological properties may differ significantly. Importantly, individual enantiomers may manifest different therapeutic effects or side effects. Therefore, the pharmaceutical industry tends to use enantiomerically pure substances in drug formulations to reduce the risk of side effects induced by the other enantiomer not only to avoid direct effect on human health but also because excluded substances from racemic drugs can cause major environmental problems in wastewater.

Over the last twenty years, technological advances in microfluidics have been reflected in the synthesis and purification of optically active chemicals. Profiting from its characteristic features, such as fast prototyping, increased process safety, scale-up by multiplication, or mass and heat transfer intensification, microfluidics has become an inherent chemical engineering tool for the control of reaction-transport processes in chemical production. Many key players in the pharmaceutical industry, such as Eli Lilly, GlaxoSmithKline, Merck, Novartis, or Bristol-Myer Squibb, invest heavily in the development of versatile micro-plants with continuous production. In this context, the manufacture of active pharmaceutical ingredients in continuous microfluidic platforms has become a standard technology. In parallel, microreactors have been successfully employed in the organic and enzymatic synthesis of many essential stereoisomers. The microscale reactions can be characterized by large yields, conversions, and selectivities, often exceeding those obtained in conventional macroreactors.

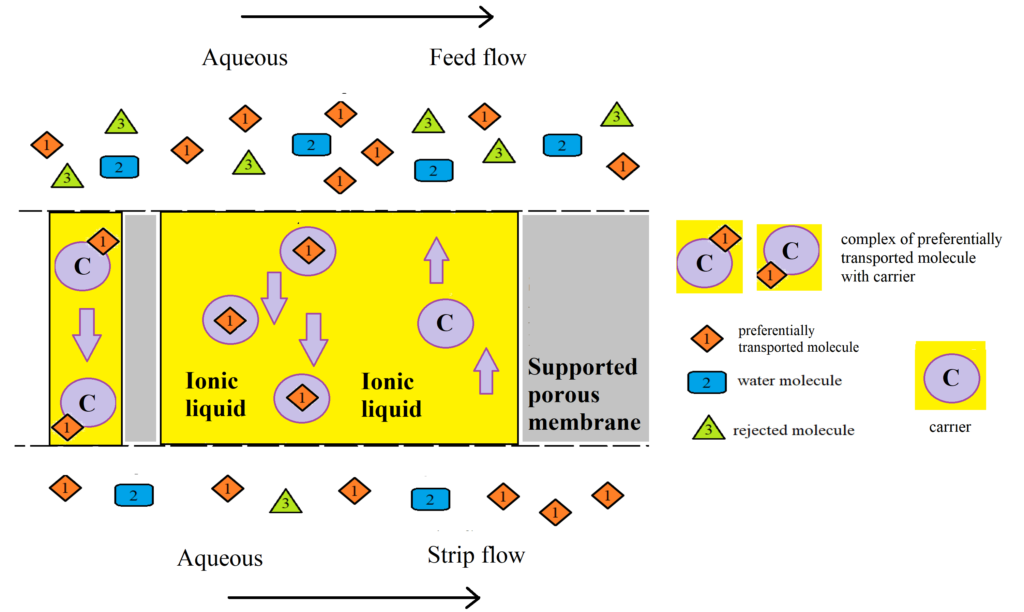

Microfluidic technologies can also employ a wide range of other chemical and physical processes. Processes such as micro-extraction, micro-adsorption, or micro-membrane separation have been successfully integrated into microreactors for the downstream separation and purification of synthesized products. Separation techniques based on membrane technologies such as nanofiltration, ultrafiltration, or reverse osmosis are also discussed in the paper. Furthermore, the mechanism of separation into individual enantiomers using liquid and polymer chiral membranes is discussed with the emphasis on the potential of chiral composite membranes.

Figure: The mechanism of separation of individual enantiomers using supported ionic liquid membranes with a carrier

- Petrusová Z., Slouka Z., Vobecká L., Polezhaev P., Hasal P., Přibyl M., Izák P.: Microreaction and membrane technologies for continuous single-enantiomer production: A review. Catal. Rev. Sci. Eng. 2021, 49 pp. https://doi.org/10.1080/01614940.2021.1977009