Photochemistry

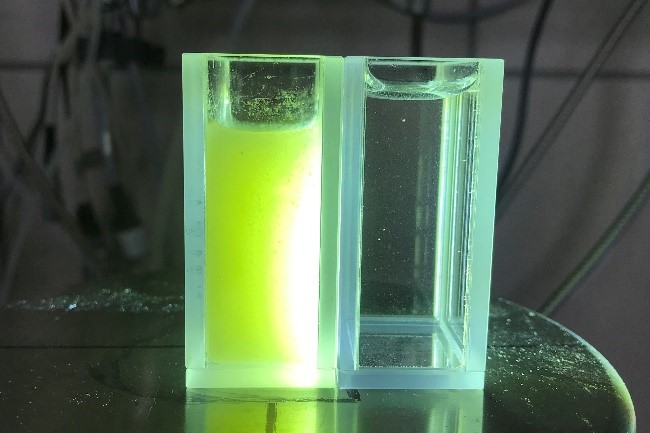

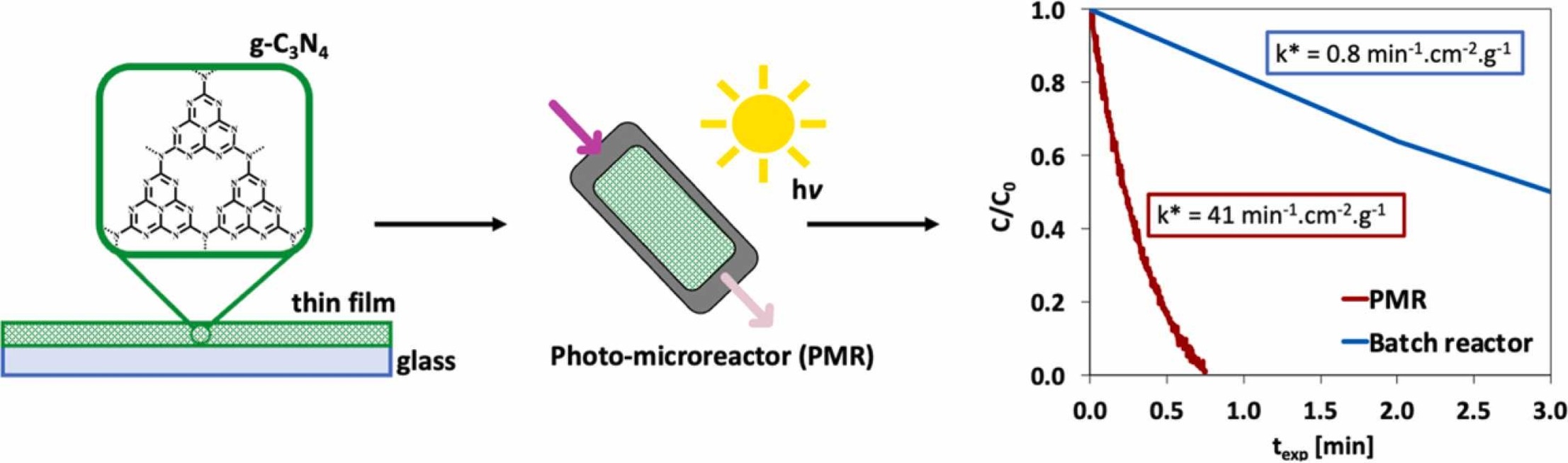

We focus on the development, testing, and characterization of highly functional thin films on the basis of graphitic carbon nitride (g-C3N4) for visible light-induced pollutant degradation and water splitting. The goal is to obtain highly active and durable photocatalytic films with application-tailored properties such as thickness, porosity, and photocatalytic activity. The cost-effective and reproducible method synthesis for highly active g-C3N4 is investigated. The photo activity of the prepared films is tested with a unique photo-microreactor of a slit geometry on an optical bench.

|

|

Batch-to-continous transformations

Batch-to-continuous transformation of phase-transfer catalyzed N-alkylation reactions for the synthesis of pharmaceuticals. This case study of N-alkylation of lysergic acid derivatives represents a fast, exothermic reaction occurring on the interface among aqueous and organic phases. Current state-of-the-art preparation includes batch process with yields of only about 80% and the use of toxic alkylation agents. Intensification of this mass-transfer limited reaction has the potential for yield increase as well as for toxic alkylation agent replacement by greener but less active alternative e.g. methyl carbonate.

|

|

3D printing in catalyst support and reactor design

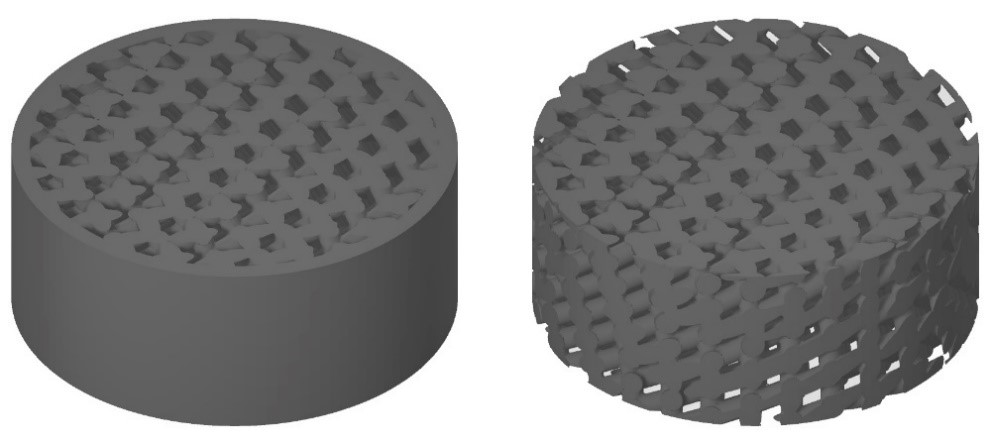

With the development of additive manufacturing technologies (3D printing), the Periodic Open Cellular Structures (POCS) are emerging as a suitable alternative to random particle beds, that represent the most utilized packed bed fillings for trickle bed catalytic reactors. POCS structures have a high potential for improving transport characteristics such as pressure drop, mass, and heat transport parameters by optimizing their geometry. The parametric set of POCS structures is designed, 3D printed, and experimentally examined for two-phase flow characteristics. The results will be compared with computational fluid mechanics (CFD) results to understand and describe the effect of geometry and topology on two-phase flow characteristics.

With the development of additive manufacturing technologies (3D printing), the Periodic Open Cellular Structures (POCS) are emerging as a suitable alternative to random particle beds, that represent the most utilized packed bed fillings for trickle bed catalytic reactors. POCS structures have a high potential for improving transport characteristics such as pressure drop, mass, and heat transport parameters by optimizing their geometry. The parametric set of POCS structures is designed, 3D printed, and experimentally examined for two-phase flow characteristics. The results will be compared with computational fluid mechanics (CFD) results to understand and describe the effect of geometry and topology on two-phase flow characteristics.

Graphitic carbon nitride thin films for light-induced photocatalysis in a slit geometry microreactor

We have successfully prepared and tested thin films based on graphitic carbon nitride in a slit geometry microreactor. Films were prepared from the mixture of milled powder catalysts and a binder. The effects of post-annealing and plasma application were studied. The photoactivity was tested with the degradation of Rhodamine B and an antibiotic Tetracycline as an emerging pollutant in wastewater. The thin film form of the photocatalyst in the microreactor had about 50x higher specific activity compared to the slurry form.

- Dolai S., Vanluchene A., Stavárek P., Dzik P., Fajgar R., Soukup K., Klusoň P., Graphitic carbon nitride thin films for light-induced photocatalysis in a slit geometry microreactor, J. Environ. Chem. Eng. 10(6), 108790, 2022. DOI

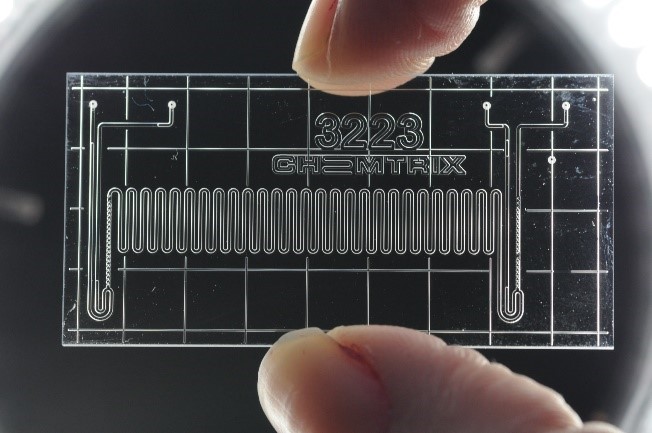

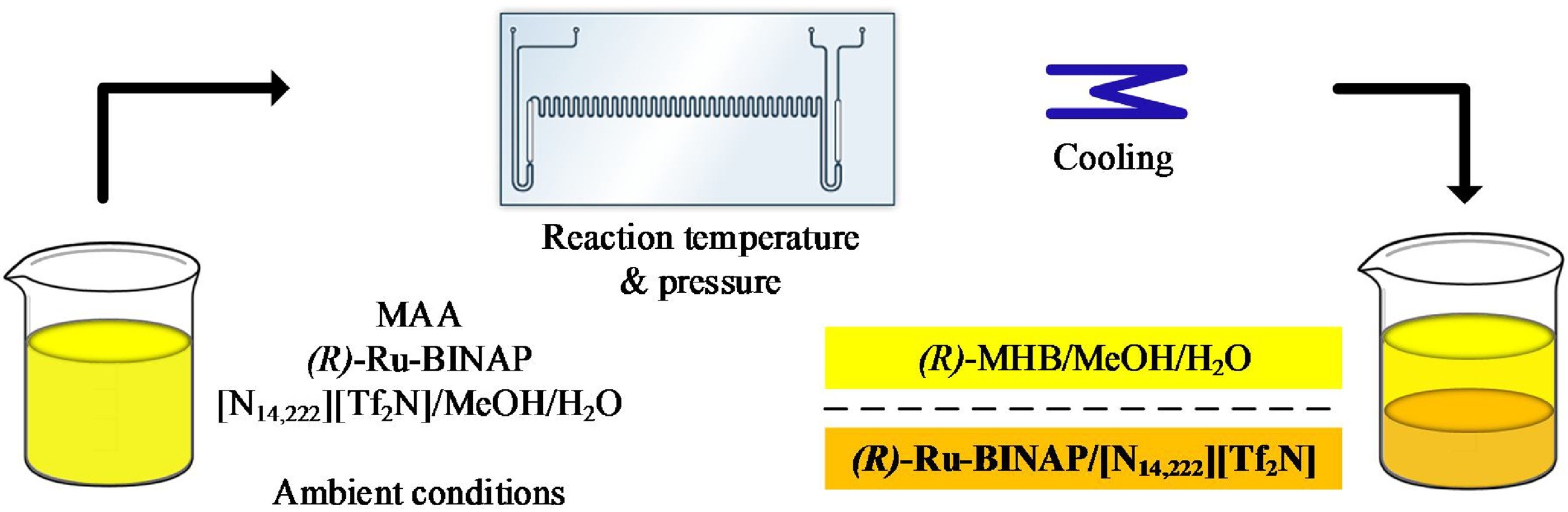

Design of the reversible biphasic arrangement in the microfluidic chip reactor for asymmetric hydrogenation reactions

We have designed the reversible biphasic system for practical use in asymmetric hydrogenation performed in a microfluidic chip reactor. Methyl acetoacetate (MAA) was transformed to (R)-methyl hydroxybutyrate over optically pure (R)-Ru-BINAP catalyst as a model reaction. The reaction mixture is homogenous under reaction conditions while after the cooling two phases are formed. The methanolic phase contains the desired product, while the ionic liquid phase contains the ionic liquid with (R)-Ru-BINAP catalyst that can be simply reused in the reaction.

We have designed the reversible biphasic system for practical use in asymmetric hydrogenation performed in a microfluidic chip reactor. Methyl acetoacetate (MAA) was transformed to (R)-methyl hydroxybutyrate over optically pure (R)-Ru-BINAP catalyst as a model reaction. The reaction mixture is homogenous under reaction conditions while after the cooling two phases are formed. The methanolic phase contains the desired product, while the ionic liquid phase contains the ionic liquid with (R)-Ru-BINAP catalyst that can be simply reused in the reaction.

- Klusoň P., Stavárek P., Pěnkavová V., Vychodilová H., Hejda S., Bendová M., Došek M., Design of the reversible biphasic arrangement in the microfluidic chip reactor for asymmetric hydrogenation reactions. Chem. Eng. Res. Des. 153, 537-546, 2020. DOI

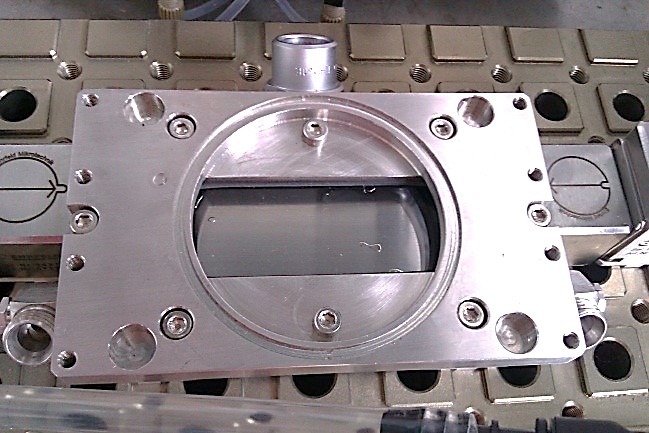

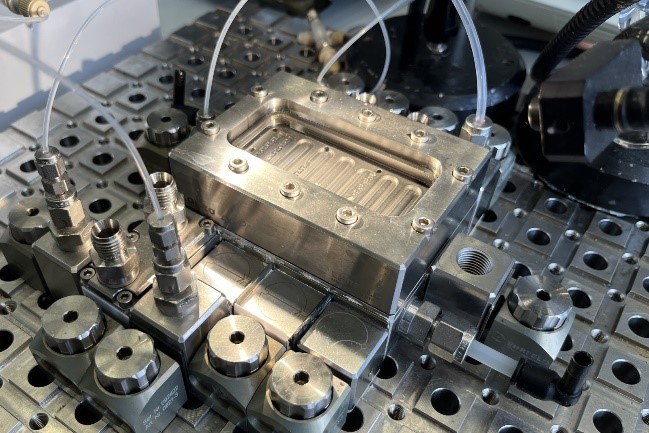

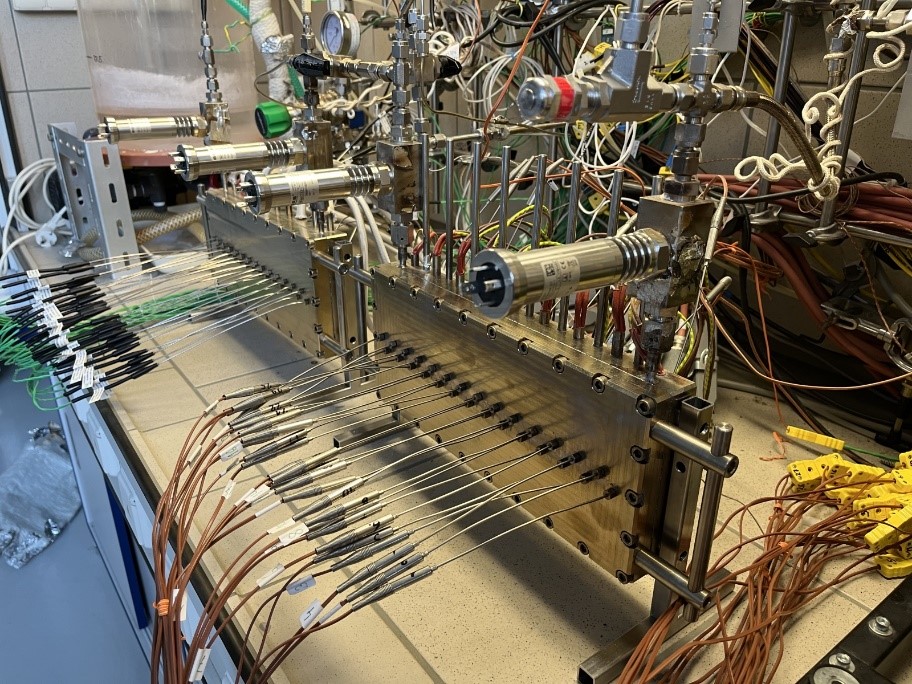

Microreactor for gas-solid catalytic reactions

The beneficial features of micro- and mili-reactors such as high surface-to-volume ratio and good control of reaction conditions (temperature, pressure) are applied to study the catalytic selective oxidations for the field of specialty chemicals. We have developed, designed, and manufactured a catalytic reactor with a long reaction path that allows us to study the oxidation process on the catalyst under industrially relevant conditions (catalyst shape, temperature, pressure, and flow conditions).

The beneficial features of micro- and mili-reactors such as high surface-to-volume ratio and good control of reaction conditions (temperature, pressure) are applied to study the catalytic selective oxidations for the field of specialty chemicals. We have developed, designed, and manufactured a catalytic reactor with a long reaction path that allows us to study the oxidation process on the catalyst under industrially relevant conditions (catalyst shape, temperature, pressure, and flow conditions).

Other results

- Dolai S., Bhunia S.K., Kluson P., Stavarek P., Pittermannova A., Solvent-Assisted Synthesis of Supramolecular-Assembled Graphitic Carbon Nitride for Visible Light Induced Hydrogen Evolution – A Review, ChemCatChem 14(4), e202101299, 2021. DOI

- Stavárek P., Lali F., Dubois J.-L., Fatty nitrile esters hydrogenation for biosourced polyamide polymers, in: Industrial Green Chemistry, , Dubois J.-L. (Eds.), De Gruyter 2020, Chapter 4, pp. 77-114. DOI

- García S., Poulston S., Stavarek P., Ni-free hydrogenation of natural products for the personal care industry: case study, squalene hydrogenation, in: Industrial Green Chemistry, , Dubois J.-L. (Eds.), De Gruyter 2020, Chapter 5, pp. 115-138. DOI

- Stavarek P., Kluson P., Penkavova V., Bandzuch J., Verified technology: Continuous production of acrylic resin by radical polymerization, in: CAS (Ed.) Czech Republic, 2019. RIV

- García S., Poulston S., Modeshia D., Stavarek P., Ujcic M., Lali F., Alves M.A., Araújo J.D., Krusche M., Ullrich F., Maier D., Continuous Production of Squalane Using 3D Printed Catalytic Supports, Johnson Matthey Technology Review 63(3), 191-204, 2019. DOI

- Gaálová J., Hejda S., Stavárek P., Sýkora J., Fajgar R., Kluson P., Izák P., Pervaporation of (R)/(S)-methyl 3-hydroxybutyrate (∑MHB) from a mixture containing an ionic liquid, methanol and Ru catalyst, Sep. Purif. Technol. 222, 45-52, 2019. DOI