Development of new processes for the treatment or recycling of waste and waste materials

With the development of new technologies and materials, new types of municipal and industrial wastes are generated that need to be treated according to the principles of the circular economy. Therefore, this theme focuses on both the existing difficult-to-treat wastes and the development of recycling methods for newly emerging wastes, with an emphasis on maximizing the recovery of valuable raw materials and their environmentally sound treatment. Areas of interest include:

- Material flow analysis of new waste types;

- Environmental impact and characterization of new waste types;

- Recovery of metals and rare earth metals from various types of e-waste;

- Recovery of valuable components from mining residues;

- Recovery of industrial residues as secondary resources;

- Processing of various components of municipal waste (plastics, textiles, etc.).

Waste-to-energy

Waste-to-energy is a key technology for the treatment of municipal solid waste and unavoidable waste that cannot be recycled. The energy recovery process produces solid residues, namely fly ash and bottom ash, which can be used as secondary raw materials. Our research efforts focus on the following aspects:

- Processing and material recovery of fly and bottom ash: We are developing methods to process and recover these solid residues. In the case of fly ash, we focus on the removal of hazardous properties and the possibility of extracting salts and metals. In the case of bottom ash, we are developing efficient processes to recover valuable components, especially non-ferrous metals, and exploring the possibilities for its use in the construction industry;

- Utilization of process wastewater: We are investigating the possibility of utilizing process wastewater, for example in the production of gypsum. In this way, we contribute to the efficient use of residues from waste-to-energy technologies and minimize the negative impact on the environment.

Material and energy recovery of waste biomass

In addition to combustion, we focus on the pyrolysis and gasification of solid fuels into higher-value products, the understanding of the influence of process conditions on the quality of gaseous and solid products, and the development of processes for the purification of gaseous products. In this area, recent work has focused on the gasification of woody biomass to produce biochar for soil amendment or pollutant adsorption, and the treatment of sewage sludge by pyrolysis and combustion processes with subsequent recovery of solid products, e.g., for use as a soil supplement (pyrolysis) or for phosphorus recovery (combustion).

Flue gas treatment for the achievement of low concentrations of pollutants

Flue gas treatment is one of the key research challenges in the face of increasingly stringent emission limits. In this area, we are working on the development of efficient processes for the removal of mercury from flue gases and processes for the removal of acidic compounds, using both dry and wet processes, or developing completely new concepts, for example using membrane separation. Finally, we are focusing on reducing greenhouse gas emissions from energy processes, including analyzing the impact on energy plant operations.

Preparation, production, characterization and the use of biochar

In the Research Group of Waste Management and Sustainable Technologies, the production of high-temperature biochar as an energy by-product is being addressed by a team led by Associate Professor Pohořelý. One of the main results was a Patent for a gasification unit that enables combined heat, power, and biochar production, based on which an industrial unit was put into operation in the town Zlatá Olešnice. Simultaneously, the team participated in the commissioning of other gasification units in the Czech Republic to produce low-tar generator gas. As a result of the cooperation and adjustments to the operating parameters of these gasification units, very low tar levels in the generator gas of 5-50 mg/m3 were achieved. The energy by-product (solid residue) met the European Biochar Certificate (EBC) quality standards for use as biochar. The biochar had a specific surface area of 350-700 m2/g and very low volatile content, H/C molar ratio, and PAH content (Fuel (2020)).

In the Research Group of Waste Management and Sustainable Technologies, the production of high-temperature biochar as an energy by-product is being addressed by a team led by Associate Professor Pohořelý. One of the main results was a Patent for a gasification unit that enables combined heat, power, and biochar production, based on which an industrial unit was put into operation in the town Zlatá Olešnice. Simultaneously, the team participated in the commissioning of other gasification units in the Czech Republic to produce low-tar generator gas. As a result of the cooperation and adjustments to the operating parameters of these gasification units, very low tar levels in the generator gas of 5-50 mg/m3 were achieved. The energy by-product (solid residue) met the European Biochar Certificate (EBC) quality standards for use as biochar. The biochar had a specific surface area of 350-700 m2/g and very low volatile content, H/C molar ratio, and PAH content (Fuel (2020)).

Our expertise in the production of high-temperature biochar led to the establishment of collaborations with other research groups from institutions such as the Czech University of Life Sciences in Prague, the University of Chemistry and Technology in Prague, and Foshan University. These institutions have used our expertise in the preparation, production, and characterization of biochar properties for research work in the fields of sustainable agriculture (Soil Tillage Res (2018), Sci Total Environ (2022a), Chemosphere (2022), Sci Total Environ (2022b), Soil Use Manag (2024)), removal of heavy metals and metalloids from contaminated soil and water (J Hazard Mater (2021), Chemosphere (2020), Environ Sci Pollut Res (2022), Bioresour Technol (2014), Sci Total Environ (2019), J Hazard Mater (2022a), J Hazard Mater (2022b)), or using biochar as feed component (Anim Feed Sci Technol (2022)). The above research has been supported by the following projects: Processing of residual biomass by combined thermolysis on advanced energy carriers and soil additives (MoA, QK1820175) and Long-term test of the biochar application produced from waste biomass to solve drought in intensively farmed areas of the Czech Republic (MoA, QK1910056)

- Bioresour. Technol. 171, 442–451, 2014. DOI

- Soil Tillage Res. 184, 181–185, 2018. DOI

- Sci. Total Environ. 670, 1159–1169, 2019. DOI

- Fuel 281, 118637, 2020. DOI

- Chemosphere 242, 125255, 2020. DOI

- J. Hazard. Mater. 407, 124344, 2021. DOI

- Anim. Feed Sci. Technol. 285, 115242, 2022. DOI

- Environ. Sci. Pollut. Res. 29, 37435–37444, 2022. DOI

- Chemosphere 293, 133586, 2022. DOI

- J. Hazard. Mater. 424, 127136, 2022a. DOI

- J. Hazard. Mater. 425, 127971, 2022b. DOI

- Sci. Total Environ. 814, 152772, 2022a. DOI

- Sci. Total Environ. 807, 151058, 2022b. DOI

- Energies 16, 1202, 2023. DOI

- Soil Use. Manag. 40, e12997, 2024. DOI

Material and energy recovery from sewage sludge

Currently, sewage sludge is used for agricultural purposes by direct land application or as compost and is incinerated or landfilled. In the Czech Republic, land application or composting is the predominant material used. In contrast, in Western European countries (e.g., Germany, Austria, Switzerland, the Netherlands, Belgium), incineration or co-incineration predominates. This approach is mainly based on concerns about environmental contamination by pollutants contained in sludge, such as heavy metals, microplastics, pathogens, organic pollutants (PAHs, per- and polyfluorinated substances (PFAS), flame retardants, pharmaceuticals, hormones or endocrine disruptors, etc.). These substances are removed during incineration and the resulting ash from mono-incineration is rich in phosphorus, a critical resource for the EU. For this reason, some countries, such as Germany, Austria, and Switzerland have already made it mandatory to recover (regenerate) phosphorus from the ash from the incineration of sewage sludge or directly from sewage sludge itself.

Currently, sewage sludge is used for agricultural purposes by direct land application or as compost and is incinerated or landfilled. In the Czech Republic, land application or composting is the predominant material used. In contrast, in Western European countries (e.g., Germany, Austria, Switzerland, the Netherlands, Belgium), incineration or co-incineration predominates. This approach is mainly based on concerns about environmental contamination by pollutants contained in sludge, such as heavy metals, microplastics, pathogens, organic pollutants (PAHs, per- and polyfluorinated substances (PFAS), flame retardants, pharmaceuticals, hormones or endocrine disruptors, etc.). These substances are removed during incineration and the resulting ash from mono-incineration is rich in phosphorus, a critical resource for the EU. For this reason, some countries, such as Germany, Austria, and Switzerland have already made it mandatory to recover (regenerate) phosphorus from the ash from the incineration of sewage sludge or directly from sewage sludge itself.

Within the Research Group of Waste Management and Sustainable Technologies, the team of Associate Professor Pohořelý is working on the thermochemical treatment of sewage sludge, in particular, the pyrolysis and incineration of sewage sludge with subsequent use of the solid products of the processes. The results of the research supported by projects "TH03020119 – Material transformation of sewage sludge into a fertilizer with increased phosphorus content" and "QK21020022 – Complex evaluation of the application of sewage sludge in agriculture concerning emerging pollutants" were successfully used in collaboration with HST Hydrosystémy, Ltd. to optimize the operation of a commercial unit for pyrolysis of sewage sludge at the Trutnov – Bohulavice wastewater treatment plant. The practical conclusions were that pyrolysis should be carried out at a temperature of at least 500°C (with temperatures above 600°C during nominal plant operation) to:

- achieve sufficient transfer of sludge energy to the primary pyrolysis gas, which also serves to heat the pyrolysis itself and to pre-dry the sludge,

- remove organic pollutants, pathogens, and microplastics present,

- and to create sufficient porosity in the sludge char.

(Energies 2020, J Anal Appl Pyrolysis 2021, J Anal Appl Pyrolysis 2022, Sci Total Environ 2024, Chemosphere 2021).

These results contribute to the modification of European and Czech legislation concerning the production and use of sludge-char in agriculture. For example, thanks to the cooperation sludge char produced at the Trutnov WWTP has been removed from the waste catalog and certified by the Central Institute for Supervising and Testing in Agriculture as a soil amendment (Karbofert T1) in the Czech Republic. Members of the team also act as scientific experts in the discussions led by the group for pyrolyzed sludges of the European Biochar Industry Consortium (EBI), which is tasked with initiating the modification of Regulation (EU) 2019/1009 of the European Parliament and of the Council laying down rules on the making available on the market of EU fertilizing products by creating its own Component Material Category for pyrolyzed sewage sludge.

In addition, the group led by Associate Professor Pohořelý is working on the following topics:

- Fluidized bed incineration of sewage sludge with the possibility of using the ash to recover phosphorus and other useful raw materials, which has been described in detail in a review article in J Environ Manage 2021.

- Legislation in the field of sewage sludge management at the national and international levels, e.g. in specific collaboration with scientific colleagues in Japan, conclusions published in Clean Techn Environ Policy 2023.

- Removal of per- and polyfluorinated substances (PFAS) and organic fluorine from sewage sludge by pyrolysis at laboratory and application scale at the Bohuslavice - Trutnov WWTP, in cooperation with the Institute of Microbiology of the CAS, with results published in Biochar 2024 – in press.

- Research on sewage sludge incineration, supported by the project "TK05020001 Fluidized bed technology for decentralized energy utilization of dried sewage sludge", which will result in project documentation and a prototype of a 0.5 MW fluidized bed incinerator.

- Energies 13, 4087, 2020. DOI

- Chemosphere 265, 129082, 2021. DOI

- J. Anal. Appl. Pyrolysis 156, 105085, 2021. DOI

- J. Anal. Appl. Pyrolysis 161, 105387, 2022. DOI

- J. Environ. Manage. 315, 115090, 2022. DOI

- Clean Techn Environ Policy, 2023. DOI

- Sci Total Environ. 918, 170572, 2024. DOI

- Biochar, 2024 in press

Metal recovery from bottom ash and its utilization

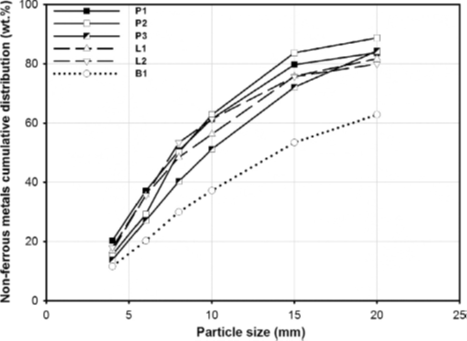

Bottom ash is the main solid residue from waste-to-energy. The composition of bottom ash reflects the composition of the incinerated waste and depends on the character of the collection area, waste sorting efficiency in the collection area, and the type of buildings in the collection area. The influence of these factors on the content of ferrous and non-ferrous metals and glass was determined based on a detailed analysis of the composition of bottom ash from three waste-to-energy plants in the Czech Republic and the analysis of their collection areas. One of the key factors was found to be the ratio of municipal and commercial trader waste. Higher content of recyclable components such as ferrous and non-ferrous metals was found to be in the bottom ash from big city waste-to-energy plants (e.g. in Prague) that incinerate solely municipal waste (Waste Manage. 2018).

Bottom ash is the main solid residue from waste-to-energy. The composition of bottom ash reflects the composition of the incinerated waste and depends on the character of the collection area, waste sorting efficiency in the collection area, and the type of buildings in the collection area. The influence of these factors on the content of ferrous and non-ferrous metals and glass was determined based on a detailed analysis of the composition of bottom ash from three waste-to-energy plants in the Czech Republic and the analysis of their collection areas. One of the key factors was found to be the ratio of municipal and commercial trader waste. Higher content of recyclable components such as ferrous and non-ferrous metals was found to be in the bottom ash from big city waste-to-energy plants (e.g. in Prague) that incinerate solely municipal waste (Waste Manage. 2018).

The effective recovery of these metals is due to the wet character of bottom ash technologically intricate. Nowadays, there is a wide variety of different technologies and technological concepts of separation with various demands and efficiency; hence, each technological unit is nearly unique. However, the principles are more or less the same and involve pretreatment steps (aging, sieving, crushing, etc.) with subsequent separation by means of magnetic, eddy current, and sensor-based separators. The state of the art for metal recovery was summarized by an international team in 2020 (J. Hazard. Mater. 2020). Based on the above-mentioned knowledge, a pilot plant with a capacity of several tons per hour was constructed within the Prague WtE plant for the effective recovery of non-ferrous particles over 3 mm. The results from the pilot plant testing and know-how will be used for the construction of a real-scale plant.

Bottom ash after metal recovery can be used in various applications in the construction industry. Possible ways of utilization, as well as technical and environmental criteria setting for safe utilization, are regulated in national law. A comprehensive overview of legislation for bottom ash in Europe and the analysis of criteria for utilization were prepared by the international team in a review paper (Waste Manage. 2020).

- Waste Manage. 73, 360-366, 2018. DOI

- Verified Technology for Separation of Non-ferrous Metals from Incineration Bottom Ash. 2019.

- Equipment for separating non-ferrous metals from a bulk mixture (Utility model) 2019, CZ33130.

- J. Hazard. Mater. 393, 122433, 2020. DOI

- Waste Manage. 102, 868-883, 2020. DOI

Determination of mercury behaviour during combustion processes

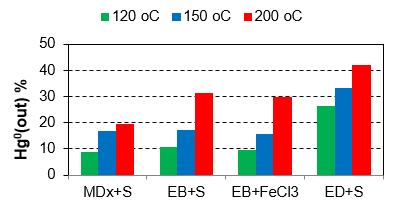

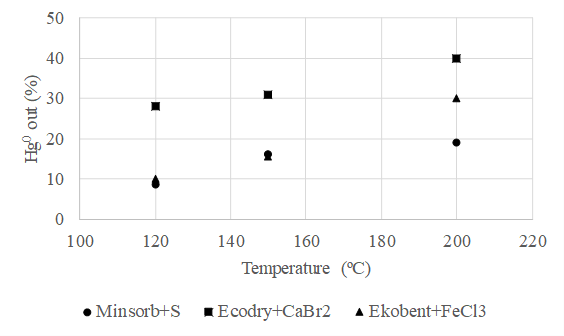

Mercury is one of the most significant pollutants in terms of emissions from coal combustion. For its effective capture, it is necessary to have a knowledge of its speciation. In the frame of extensive experimental activity, the behaviour of mercury during combustion was clarified and the key factors influencing its speciation were determined, and possible mercury capture methods were experimentally verified. There are three important factors for the effective sorption of mercury (esp. in the form of the vapour of elementary mercury Hg0):

Mercury is one of the most significant pollutants in terms of emissions from coal combustion. For its effective capture, it is necessary to have a knowledge of its speciation. In the frame of extensive experimental activity, the behaviour of mercury during combustion was clarified and the key factors influencing its speciation were determined, and possible mercury capture methods were experimentally verified. There are three important factors for the effective sorption of mercury (esp. in the form of the vapour of elementary mercury Hg0):

- specific sorbent surface (should be, if possible, more than 200 m2/g),

- sorption temperature (suitable to avoid temperatures above 150 °C),

- and impregnation (oxidizing compounds with chlorides and bromides, and agents with sulfur, in elementary form as well as polysulfides).

During the sorption of Hg0 and mercury compounds on ashes, the decisive factors are the content of unburned carbon, chloride content, specific surface area and sorption temperature. The content of water vapour usually slightly hinders the sorption of mercury on sorbents. At higher ratios of HCl/SO2 concentrations in the flue gas and oxygen content above approx. 4 vol. %, Hg0 is oxidized in the gas to HgCl2. The oxidation depends on the temperature, catalytically active surface, and reaction time. Organometallic mercury compounds are transformed in the combustion processes to a mixture of Hg0 vapour and inorganic compounds (esp. HgCl2). In flue gas with a very low content of VOC, almost no organometallic compounds are formed. When mercury is to be removed by wet methods together with SO2, it is necessary to pay attention to the so-called re-emission of mercury caused by the reduction of Hg2+ to Hg0 with subsequent volatilization into the flue gas. These findings were published in a number of original works and serve as a base for the development of capture technology for mercury in flue gas.

During the sorption of Hg0 and mercury compounds on ashes, the decisive factors are the content of unburned carbon, chloride content, specific surface area and sorption temperature. The content of water vapour usually slightly hinders the sorption of mercury on sorbents. At higher ratios of HCl/SO2 concentrations in the flue gas and oxygen content above approx. 4 vol. %, Hg0 is oxidized in the gas to HgCl2. The oxidation depends on the temperature, catalytically active surface, and reaction time. Organometallic mercury compounds are transformed in the combustion processes to a mixture of Hg0 vapour and inorganic compounds (esp. HgCl2). In flue gas with a very low content of VOC, almost no organometallic compounds are formed. When mercury is to be removed by wet methods together with SO2, it is necessary to pay attention to the so-called re-emission of mercury caused by the reduction of Hg2+ to Hg0 with subsequent volatilization into the flue gas. These findings were published in a number of original works and serve as a base for the development of capture technology for mercury in flue gas.